Nick Harvey’s home of Davis in eastern Carteret County proudly displays Harvey’s creations each year. |

SMYRNA — People have been catching blue crabs for thousands of years using a variety of methods. Catching them became a lot easier in 1920 when Benjamin Lewis invented the crab pot, a wire trap that was so eagerly accepted by crabbers that Lewis patented his device in 1928.

At the time, he had no way of knowing that his contraption designed to capture the savory crustacean, with a Latin name that means “beautiful swimmer,” would inspire what has become a beautiful coastal Christmas tradition.

Supporter Spotlight

The so-called “Maryland crab pot” is shaped like a cube and is roughly two feet tall on all sides. It has seen very few modifications since the original plan. The chicken wire mesh is now a little stouter and covered with a protective plastic coating. This plastic covering extends the life of the pots by slowing the corrosive effects the saltwater has on the metal mesh. Over the years, different colors of coating have been available, and some crabbers are loyal to a particular color because they are convinced that it attracts more crabs.

It was green that one day sparked the imagination of Neal “Nick” Harvey, a commercial fisherman from Davis in eastern Carteret County, a part of the county known in these parts as Down East.

Harvey, an independent waterman, made a living harvesting the riches of the sea and providing the necessary gear to help others do the same. He enjoys the “seasons of the water” that provide a variety of fishing opportunities throughout the year. Harvey knows the drift of the ocean currents up and down the East coast and has piloted a trawler for days without rest. He has pulled shrimp and flounder from the sea and ventured into the rivers and sounds to collect clams and scallops. However, Harvey was confident enough to step away from the boat to make nets and crab pots that he sold by the thousands.

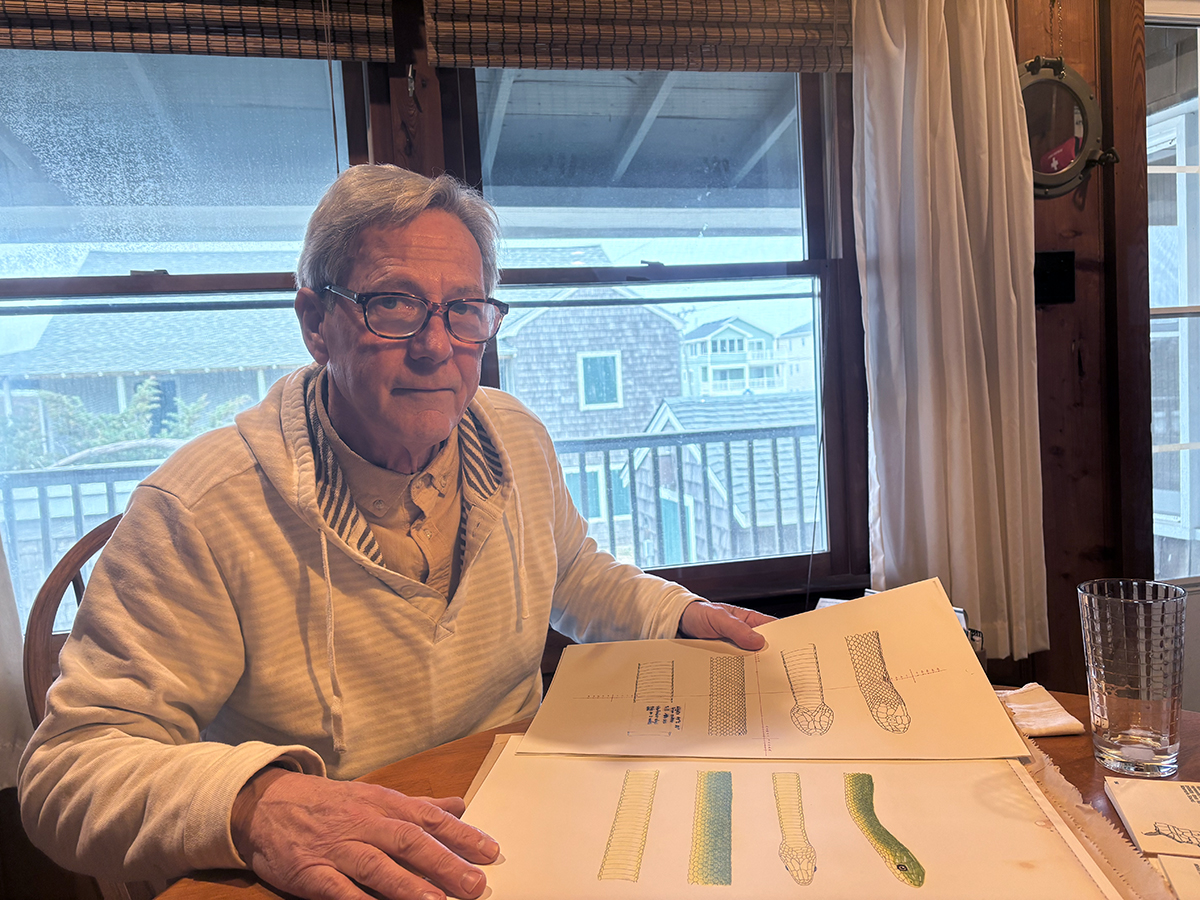

Neal “Nick” Harvey patented his creation. |

One day, with Christmas approaching, Harvey decided to brighten up the confines of his crab pot making shop with some Christmas decorations. He found some discarded pieces of the crab pot wire mesh and began shaping the pieces until they had the distinctive uniform tapered shape of a Christmas tree. He displayed his creation in a large window of the shop that faced the highway.

Soon, family, friends and neighbors stopped by to see the tree and wanted one as well. Harvey started selling the tree at the annual Core Sound Waterfowl Weekend at the Core Sound Waterfowl Museum and Heritage Center on Harkers Island. After the first day of sales, he had to hurry back to the shop and work through the night to make more trees for the following day at the festival.

Supporter Spotlight

From 2000 to 2009, Harvey and his crew did nothing but make crab pot Christmas trees. The success of the tree and its potential created such a demand on body, mind and spirit that in 2009 Harvey sold the business. Before doing so though, Harvey patented his creation and he still retains the patent rights.

Today, the trees are manufactured by Fisherman Creations Inc., owned by Don Acree, in the Down East community of Smyrna. Acree has marketed the tree nationally and has regional distributors and dealers. The tree has been set up in homes in all states across the country including Hawaii and Alaska. It has been shipped to numerous foreign countries and has been proudly displayed by military troops in Afghanistan.

The crab pot trees make an impressive display when massed together.

The trees are locally appealing for their cultural connection to the traditional self-sufficient lifestyle of the Down East fishing community. They are also a symbol of the clever ingenuity of working waterman. Yet, they are also attractive to anyone who loves to display a unique creative Christmas decoration. The trees come in a variety of heights from 1.5 feet to 8 feet and can be adorned with an array of lighting choices.

On a beautiful day, I decided to take a drive to Smyrna to see how a crab pot Christmas tree was made. I pulled into the lot of the shop and was immediately greeted by the security officer, a dog that let everyone within ear shot know that an intruder had breached the perimeter. The pooch barked and snarled as it circled around me while I approached the shop entrance. As the shop door opened, a man stepped out and sternly said, “Hatch, behave.”

Hatch settled down, let me pet him a few times and quickly became my friend. His owner, George Brearey, is the manager of Fisherman Creations and he generously agreed to show me around the shop. Brearey actually had little time to indulge me as he was bombarded with continuous phone calls about orders, shipments and dealers. I wandered around the shop filled with rolls of crab pot wire, shipping boxes, tree lights and stacks of trees of assorted heights in various stages of construction. Hatch escorted me, keeping me under constant surveillance. But I did get to see one of the tricks of the trade.

Mike Wells cuts wire at the shop in Smyrna, |

Shipments of wire await being fashioned into Christmas trees, while Hatch keeps watch. |

The constant chatter of a power tool got my attention and I found a man wielding a large electric shearing hand tool. Mike Wells was cutting through a thick stack of pre-cut crab pot wire lengths. Without, what appeared to me, any calculations, Wells maneuvered the power tool through the stack of wire causing me to wonder what he was making. As he cut, the surplus wire fell away revealing the parallel half shape of a tree. I asked Wells how he did that without a template and he said “I’ve done it so many times I don’t need one.”

Turns out Wells has been helping make the trees since the idea was born in Harvey’s shop. Wells explained that there is a mathematical equation that creates the perfect taper from the top to the bottom of the tree panel. Each tree height has a different equation. He told me the equation so quickly that it would be unlikely that I could remember it. I also heard a low growl from Hatch.

I wandered into another room of the shop that was brightly lit and filled with erect trees on pedestals. Here a team of workers were busy putting strands of lights on each tree. One of the appeals of this tree is that they are pre-strung with lights and the tree panels can fold together allowing for flat space saving storage with the lights still attached. Each employee was focused on stringing a separate tree while chatting and teasing each other. They even coaxed an employee to tell me an old story about a long lost love. Their cheerful mood reminded me of a room full of Santa’s workshop elves.

As I was leaving the shop, I could overhear Brearey talking to what I assumed to be someone interested in becoming a potential dealer. He said, “All you have to do is open up the tree, set it on the display floor, plug in the lights and they will sell themselves.”

That appeared to be good advice judging from the large stack of packaged orders sitting near a large bay door waiting to be shipped. Most of the stack was going cross country to the state of Washington.

Later that day, as I talked to Harvey in the original shop where he invented the Core Sound Christmas Tree, I asked him how it felt to see his creation decorating his town and on utility poles throughout the community and did it make him feel good that the trees have been shipped all over the United States and to many other countries as well?

Literally, as I am asking this, I can see a neighbor across the street walk into their front yard and begin setting up two crab pot trees. I had proposed a question that afforded an opportunity for Harvey to puff up his chest and brag a little. Yet, very humbly, Harvey simply said, “I never expected for so much to come out of a few pieces of scrap crab pot wire.”