As weather-related disasters impact shorelines throughout the world, there is an increasing need to know how to respond. The physical devastation, the loss of power, communication — all of it is part of the recovery process.

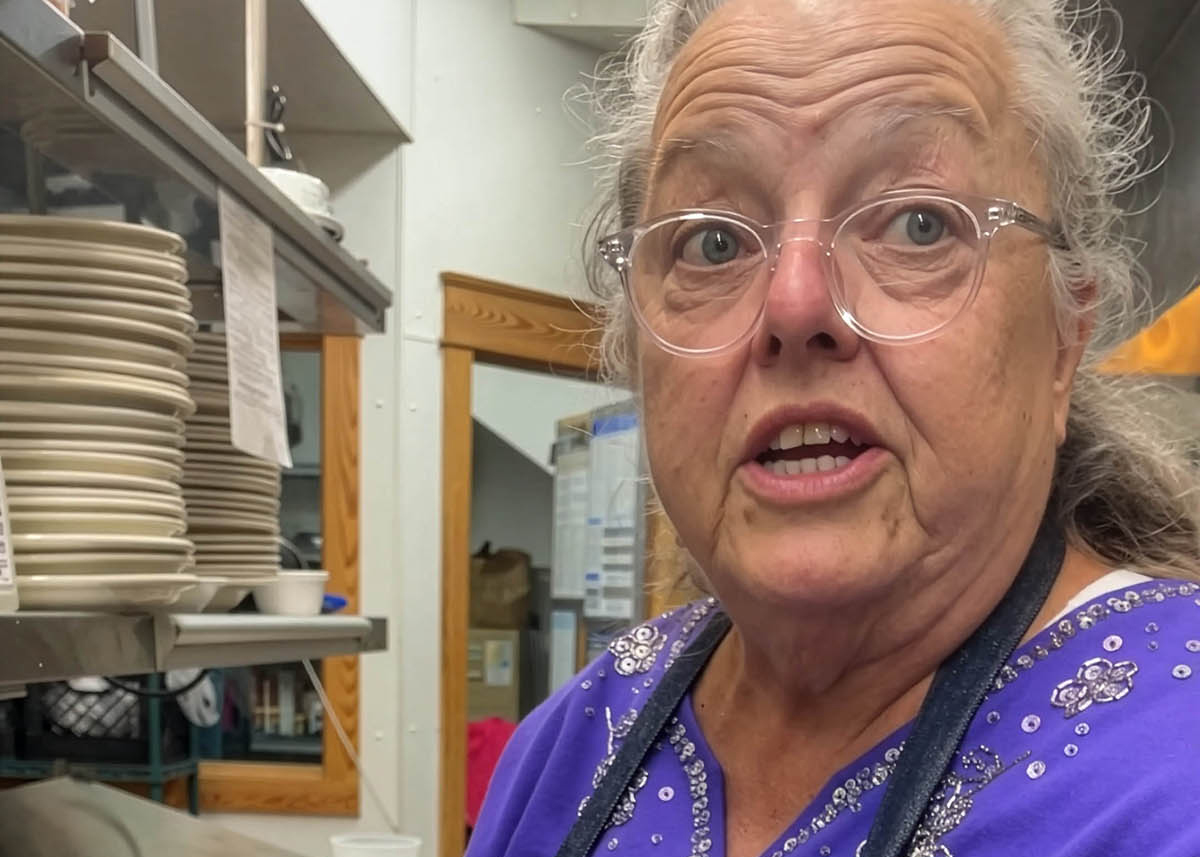

But nothing happens without clean water, something George Bonner, director of the North Carolina Renewable Ocean Energy Program at the Coastal Studies Institute in Wanchese learned in 1998 when he was serving with the Coast Guard.

Supporter Spotlight

“I was in Puerto Rico after Hurricane George back in ’98. We lost power and water. You realize that power is important but maybe more important is to go the toilet and take a shower. It’s kind of like Maslow’s hierarchy of needs — water’s way out there in my mind, above electricity.”

But how can fresh water be produced if there is no energy in the power grid.

Addressing that problem was at the heart of the U.S. Department of Energy’s Waves to Water Prize, the final phase of which was held April 3-6 at Jennette’s Pier in Nags Head. Four competitors took to the waters off the pier, deploying wave-powered desalination devices. The devices worked as expected, producing fresh water from seawater, and provided much-needed insight into how to improve systems, said Scott Jenne, the National Renewable Energy Lab principal investigator for the Waves to Water Prize.

“This competition shows that wave-powered desalination systems are capable of supplying clean water to people in coastal locations, including in disaster-recovery situations,” he said in a statement from the lab after the event.

“These teams deserve a lot of recognition for doing something that very few people in wave energy have ever achieved. They all built functioning in-water prototypes,” he wrote about the competition in an email response to Coastal Review. “There’s still a long road to go before we understand every challenge, but we learn a lot every step of the way.”

Supporter Spotlight

The CSI team was responsible for deploying the devices. Dr. Mike Muglia and Dr. Lindsay Dubbs, both working with the North Carolina Renewable Ocean Energy Program, were lead investigators for the project and handled getting the devices in the water. According to Muglia, there were numerous challenges involved with that.

“There was the logistics of getting all the equipment and for a project that we haven’t done before,” he said. “There was lots of different delays with supply chain issues for the competitors, as well as some of the companies that rent us the cranes and deliver the cranes and set up the fence (for the deployment area at the end of Jennette’s Pier).”

The biggest challenge, though, may have been the weather. The devices were placed in the water April 3, and that night and into the next day the winds gusted to more than 30 knots with waves breaking in the deployment zone at the end of Jennette’s Pier. For the competitors, it was the first time in the water experiencing conditions so harsh, and all four devices broke from their moorings and had to be retrieved.

“Figuring out how to build a mooring for the whack in a breaking wave, which is what we experienced, I think was a surprise for them,” Muglia said.

The devices were retrieved — two on land and two at sea but accessible.

Regardless of the weather, what the competitors accomplished was what the National Renewable Energy Lab had hoped would happen.

“Every team was able to produce drinkable water from the ocean using nothing but wave energy,” Jenne wrote, adding, “Very few individuals have ever done that outside of a lab environment.”

Competitors were vying for several awards, including a grand prize of $500,000 that went to the Canada-based Oneka Technologies Snowflake. The design also was awarded an additional $125,000 prize for producing the most water: 1,000 liters per day. If used only as drinking water, that would be enough to sustain 400-450 people per day.

Perhaps most remarkably, all the units that were put into the ocean used readily available parts.

“Operationally, you don’t want to have really fancy, complex parts,” said Dragan Tutic, CEO and founder of Oneka Technologies. “So, the whole system is made with a readily available things you can buy at the hardware store.”

Oneka has been working with wave-powered desalination since 2017 and was the company with the most experience in building and deploying the units, and most with much larger capacities. The Snowflake, however, has an important role.

“It’s our small-scale unit that’s intended for emergency relief, that’s easy to ship and deploy with really minimal equipment,” Tutic said.

The harsh conditions at Jennette’s Pier were a test for improvements that had been made earlier in the year on an earlier version of the Snowflake.

“Snowflake 2 that was deployed in North Carolina, that one has a much stiffer float which, even in the very harsh condition — the system itself is still pretty intact,” Tutic said. “There are some minor things that we corrected, but the device itself as a whole, it was very resistant to even the very harsh conditions.”

Originally scheduled for five days, the Jennette’s Pier completion had to be shortened because of weather conditions. However, Muglia was quick to note that the information learned will be invaluable.

“It was definitely not a failure,” he said. “We’re going to learn how we could make these better and move forward.”

Jenne with the National Renewable Energy Lab echoed the point in his email, saying the conditions were something they knew they would eventually have to face. “The conditions we saw have already informed NREL and the Water Power Technology Office at DOE what research we need to focus on next,” he wrote. “There’s still a long road to go, but we learn a lot every step of the way.”

Prize winners

The Oneka Snowflake took home the $500,000 grand prize, and the team received an additional $125,000 for producing the most water with their device.

Another $125,000 was awarded to Team Water Bros, whose members hail from the University of North Carolina Charlotte, for delivering the lightest device.

And $125,000 was disbursed among the four teams for the Simplest Assembly award. The amounts awarded, based on the time taken it took each team to assemble its device, were as follows:

- Oneka: $80,000

- Mark Zero Prototypes, LLC: $20,000

- Water Bros: $17,000

- Project 816: $9,000

Finally, $125,000 was also distributed among the teams based on the ease of deployment and retrieval for each device. The awards were as follows:

- Mark Zero Prototypes LLC: $38,000

- WATER BROS: $36,000

- Project 816: $26,000

- Oneka: $24,000

Since the teams were unable to test their devices for the full five-day window because of foul weather, each will have the opportunity individually test their own device again in North Carolina this summer.