The light first shone over the Atlantic Ocean Dec. 1, 1875, and since that moment, every night for 145 years the Currituck Beach Lighthouse has beamed a warning to ships at sea.

Every night except one, that is.

Supporter Spotlight

On July 22, 1880, 2nd Assistant Keeper Thomas Everton failed to pump oil into the lantern, allowing the light to go dark. That was the determination of Keeper Lewis Simmons and 1st Assistant Keeper Horatio Heath.

Their findings, evidently, were supported by the Lighthouse Board, the government agency that oversaw lighthouse operations until 1910. Simmons had been relieved of duty by that August.

Navigational necessity

The United States government had known for some time that a light was needed at Currituck Beach. Money was allocated in 1854 and a Fresnel lens ordered from France, but the Civil War stopped any plans for construction and the lens eventually made its way to Key West.

After the war, the need to repair or replace existing lighthouses was so great that funds were immediately depleted. Nonetheless, the Lighthouse Board noted in its 1871 report that, as the Bodie Island Lighthouse neared completion, the next project had to be Currituck Beach.

“With the completion of the Light house at Body’s Island there will remain only one important interval of unlighted coast on the Atlantic from the St. Croix (River), Maine, to about Mosquito Inlet, on the coast of Florida,” the report noted. “That dark space will be embraced between Cape Henry and Body’s Island, a distance of eighty miles and an unlighted space of forty miles, at the center of which there should be a first-order Light, so that from Cape Henry to Cape Hatteras the broad side of that long stretch of low land and dangers could not be approached … without seeing a warning of danger.”

Supporter Spotlight

In 1873, land was purchased for the lighthouse. Construction began in 1874 and in 1875 the Lighthouse Board reported, “The tower is nearly finished and it is expected that the light will be exhibited about December 1… The establishment of this light completes the chain from the mouth of Chesapeake Bay to Cape Hatteras and supplies a want long felt by commerce.”

Once completed, there was a lighthouse keeper living on the grounds until 1939, when the Coast Guard took over management of the light and automated the beacon with an electric light.

The last lighthouse keeper was William Tate, the same William Tate who had invited the Wright Brothers to Kitty Hawk in 1900.

Without a keeper and staff to maintain the lighthouse, the two keepers’ homes and the lighthouse grounds fell into disrepair. By 1980, the site was an eyesore and the nonprofit Outer Banks Conservationists, or OBC, stepped in to begin renovations.

The OBC owns the grounds today, thanks to a 2003 decision by the Department of the Interior deeding the property to the organization, after legal challenge from the county for ownership.

The setting is beautiful. The brick lighthouse reaches 162 feet into the sky with the focal plane of the lens at 158 feet above ground. The keepers’ homes have been meticulously restored to their original state and their white clapboards stand in contrast to the deep green of the lawn and red of the brick tower.

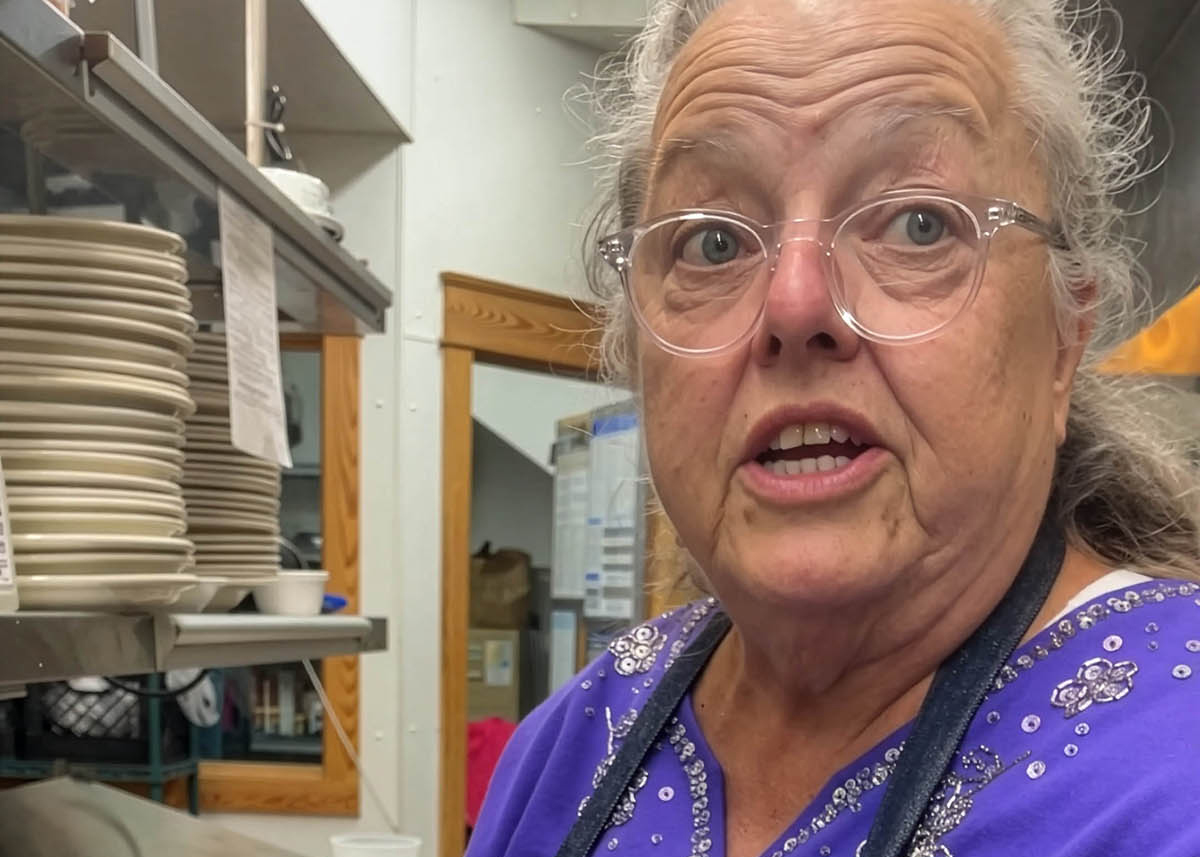

Meghan Agresto has been the site manager for the Currituck Beach Lighthouse for the past 15 years and has extensive knowledge of the history of the lighthouse. Yet as a project to repair and preserve the structure began earlier this year, new information has come to light.

For example, cornices at the focal plane part of the tower had hidden the metal plates holding everything in place. Each plate is unique and bears an identifying mark.

“These iron pieces were fabricated in Philadelphia in 1870s, and sent in pieces with Roman numerals on them,” Agresto said. “During the work here, we were be able to scrape a lot of that paint off to be able to see those numbers.”

The project was long planned. Much of the work included repairing and maintaining the lighthouse, including things the public doesn’t generally see. The metal behind the cornices are an example.

“We plan for massive projects every seven to 10 years, and this year we (the OBC) finally had enough money saved to be confident in the ability to pay for a project that was (major),” she said.

The restoration workers showed up in February, began their preliminary work and then left in March with plans to quickly return.

“They left before the North Carolina lockdown. The week they were supposed to come back, they couldn’t. And they couldn’t because they were in New York on lockdown,” she said.

The lockdown also created another problem for the renovations. The lighthouse is classified as a museum, and museums remained closed until September when Gov. Roy Cooper’s Phase 2.5 guidelines for COVID-19 eased restrictions.

The OBC’s plan depended on summer revenues from lighthouse admittance fees and gift shop sales to pay for the project.

“All of the money we would have made this summer would have gone to support it,” Agresto said. “And none of it, of course, came in.”

International Chimney Corp. of Buffalo, New York, the contractor for the project has, according to Agresto, agreed to work with the OBC on a solution.

“We had to ask them for an extension of the contract, and we started a fundraiser,” she said. The only stipulation was a request to pay for the work that had been done. “They said we’re happy to extend your contract, but could you at least pay for the things that you’ve ordered,” referring to reproduction iron castings.

Behind the scenes in some places at the lighthouse, it’s apparent that the workers had planned to return. Tools are still stored in the light tower and some scaffolding remains in place.

Visitation in September and October was better than expected, but the project must still be delayed until next year.

Sophisticated design

The lighthouse, of course, is not going anywhere. Argresto noted that the way the structure was engineered shows considerable sophistication and understanding of the latest building techniques of the time. The lighthouse is double-walled construction, a feature that was gleaned from the architects’ fact-finding trips abroad.

“Some people go visit European lighthouse establishments (where) the interior walls are cylindrical, and the exteriors are conical, leaving an unnecessarily large airspace between the two,” she explained.

The American designers, though, improved on that, using the same concept but closing the space between, adding interior space and increasing structural strength.

“They weren’t some country yokels building a building. They really knew what they were doing,” Agresto said.