BEAUFORT – It’s not magic, but what MAGIC has produced in its research based at the Duke University Marine Lab might help conjure a world less dependent upon fossil fuels.

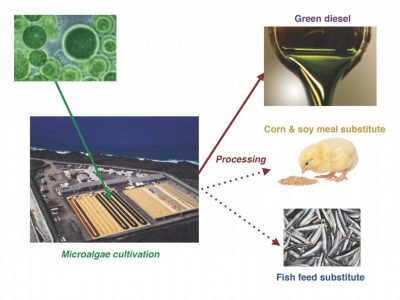

Zackary Johnson, assistant professor of molecular biology in marine science, and his multi-institutional Marine AlGae Industrialization Consortium, or MAGIC, team are on the way to figuring out a way to turn the lipids – essentially, fats – from marine microalgae into high-density liquid hydrocarbon biofuels for the aviation and cargo shipping industries, on a commercially viable scale. Perhaps just as importantly, the biomass left over after the lipids have been removed can be used to make nutritious, high-protein feed for chicken and pigs, plus aquaculture-raised seafood like shrimp and salmon, again in commercial quantities.

Supporter Spotlight

“We may have stumbled onto the next green revolution,” Charles H. Greene, a partner in the study and a professor of earth and atmospheric sciences at Cornell University, said in a news release from that school in November 2016. Johnson agrees.

“I don’t think any one technology will solve the world’s sustainable energy needs,” Johnson said last week. “Each one – solar, wind, microalgae and others – has advantages and disadvantages. But this can be a really important part of an overall solution. It’s probably not going to fuel your car or your home, but it can fuel planes and ships.”

Similarly, using the protein-rich, “defatted” biomass from the algae to produce animal feed, and potentially, high-protein food products for humans, isn’t going to totally replace other products used for those purposes; “None of us are going to be eating 100 percent algae,” Johnson said. “But again, it can play an important role.”

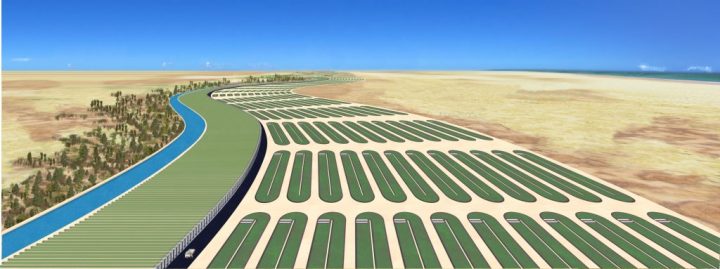

The advantage of algae production is that it can take place in many places – on land or in water – and many of those places can be in areas not used for other agricultural or aquaculture activities. Although MAGIC’s research has focused on growing the algae in loop raceway-like ponds water on land, it can be done anywhere there is sunlight for photosynthesis, Johnson said.

That means that the closer to the equator, the better. But it doesn’t require arable land, or even freshwater, and the latter is a huge benefit, because everyone knows that many areas have dire shortages of potable water for humans and animals. Even the barren desert areas of deserts of Mexico, the Middle East, Australia and North Africa are suitable.

Supporter Spotlight

And it doesn’t even require clean water. At least one group – not Johnson’s – got into the effort by using algae to clean the effluent from wastewater treatment plants. And, Johnson said, it’s even conceivable that algae could be grown for these energy and animal feed uses in polluted waters that are usually of little use to anyone, with the side benefit of cleaning those waters.

Growing enough algae to meet the current global liquid fuel demand would require an area of about 800,000 square miles, according to Johnson. That’s a little less than three times the size of Texas.

A paper MAGIC published in the journal Oceanography in December 2016 estimated a commercial microalgae production facility of about 2,500 acres would cost between $400 million and $500 million, the new paper estimates.

“That may seem like a lot of money,” Greene said in the news release after the paper came out. “But integrated solutions to the world’s greatest challenges will pay for themselves many times over during the remainder of this century. The costs of inaction are too steep to even contemplate.”

Like Greene, Johnson noted that growing algae is less land-intensive than growing the crops it would replace, so it could reduce the pressure to convert rainforests to palm plantations in Indonesia and soy plantations in Brazil.

This level of production would also yield nearly 2.4 billion tons of protein-rich byproduct for agricultural or human consumption. According to MAGIC’s paper, that’s roughly 10 times the amount of soy protein currently produced worldwide each year.

So how long before these technologies can be taken to full-scale production and start having an effect in the word?

“That’s a great question,” Johnson said. “All the economic analyses we have done say it can be done now, although we’d like it to be even more favorable. I’d say within five years there could be a viable pilot project.”

Algae’s potential as an alternative oil source was initially explored after the Arab oil embargo in 1973 led to fuel shortages and high prices at the pump in the U.S. As the crisis faded and prices dropped, the interest in algae’s biofuel potential dropped, too.

But in 2007, oil prices began to skyrocket again, finally peaking at $144 per barrel in July 2008. That sparked renewed interest and research.

Johnson, who has been at the Duke Marine Lab for eight years, got involved about that time, working in algae research with a consortium made up of a few universities and Royal Dutch Shell to study oil-producing algae. Other large oil companies, including ExxonMobil and British Petroleum, or BP, were also exploring algae’s potential as a fuel source.

The idea was that algae grow very fast, and some have a large percentage of oil in them. Because oil prices have since dropped, one problem is producing the oil from algae at competitive prices. But again, Johnson thinks it’s viable.

“Another thing we need to do, though, is make sure it’s right from a carbon-footprint standpoint,” Johnson said. It’s not just about making money for whoever eventually does it commercially, he said, it’s “about making sure it’s a good thing” overall for the environment.

Johnson said the astounding thing about the research is that it’s shown that as valuable as algae production for fuels appears to be, the protein for food – essentially an afterthought at time the research began – is even more valuable than oil, at least on paper.

That is particularly intriguing from an economic perspective because any production process can be hamstrung by waste. Algae production for fuel and algae production for protein would, or at least could be, integrated.

Johnson called it serendipitous.

“Going in, we were drawn by the oil, but the protein also has global-scale implications,” he said. “It can really make a difference. I’ve never underestimated algae – there are so many different types, and they do so many different things – but I will say that as we’ve gotten deeper into this, I never cease to be amazed at the new potentials we discover.”

For example, Johnson said, one of the great things about the protein from algae is that it’s very high in iron. As people worldwide have begun to eat less beef and more chicken and pork, people have been consuming less iron, because beef has more iron.

If you feed high-iron protein to chickens and pigs, they ingest more iron than from other agricultural food products. And if people eat those chicken and pigs, they get more iron. That’s an important consideration, when you note that per the World Health Organization, anemia affects about 1.6 billion people worldwide. That’s about 24.8 percent of the world’s population, according to WHO’s website, and highest prevalence of anemia is among preschool-age children.

Chronic anemia may result in behavioral disturbances in children as a direct result of impaired neurological development in infants, and reduced academic performance in children of school age.

So, feed high-iron animal feed to pigs and chickens, and at least potentially you can reduce the prevalence of a major health problem that affects children most frequently, and especially in poor areas.

Again, Johnson said, it’s serendipitous.

This potentially revolutionary research has been backed by a $5.2 million U.S. Department of Energy grant, and, in addition to Duke and Cornell, has involved Archer Daniels Midland, Bentley University, Bucknell University, OpenAlgae, Shell Global Solutions Inc., the University of Hawaii, the University of Nordland (now called Nord University, in Norway), The University of Southern Mississippi and Valicor Renewables.

The researchers have been systematically trying to find the best algae for the process, looking for the ones that successfully grow in larger quantities and produce a high volume of products and co-products, all in an effort to drive down the cost of commercial-scale production.

“Duke is leading the research, and I’m the primary investigator, but it really has been and is a team effort,” Johnson said. “It takes so many different disciplines to do this.”

No one scientist, he said, “knows everything,” but a team of this size and scope effectively combines the expertise of many.

“The team is thinking about this on a large, global scale,” he said when the three-year grant was first announced in 2015. “It’s thinking about how we can make a major dent in the energy demand or the protein demand. We need to do it really big to make a difference. That’s the challenge.”

And he believes the challenge is being met.

“There will be more challenges,” he said. “But I’m very optimistic.”