A University of North Carolina Wilmington professor is part of a collaboration of researchers working on a project to drastically cut carbon dioxide emissions generated in the cement-making process.

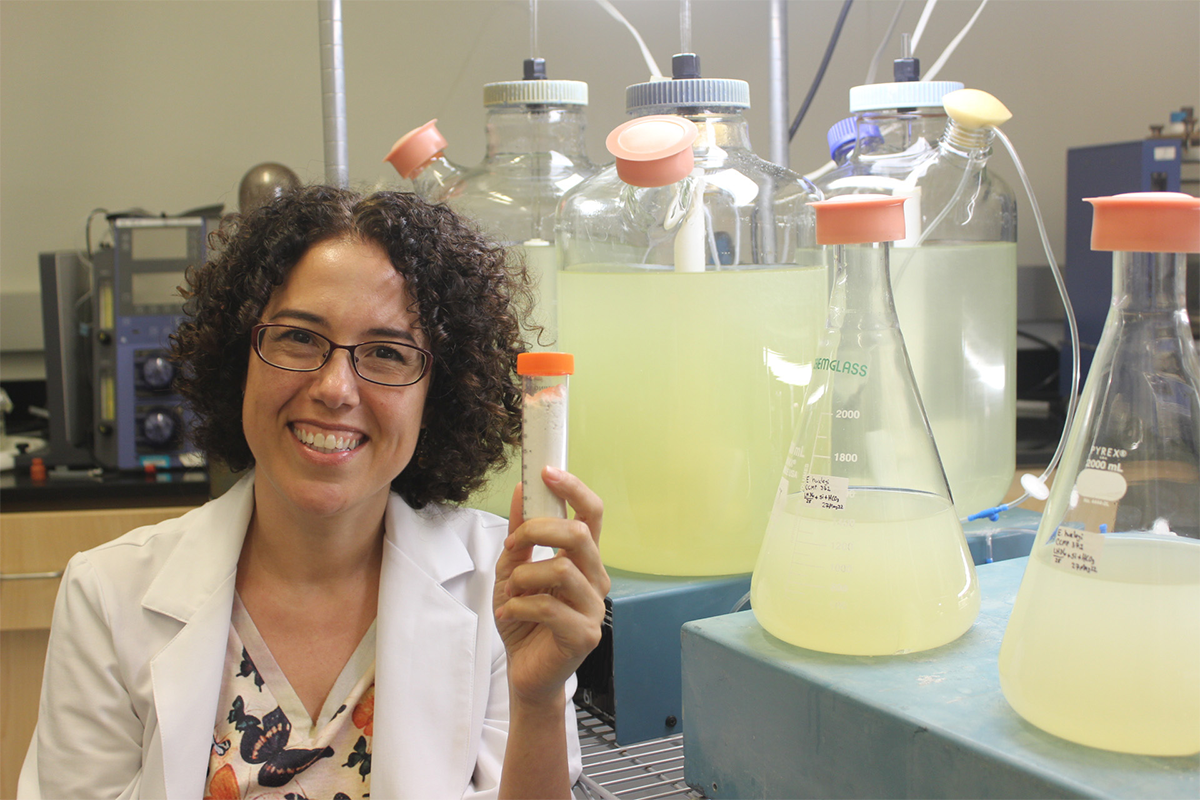

Catharina Alves-de-Souza, director of UNCW’s Algal Resources Collection, has been awarded a $1 million grant to study how to most effectively grow microalgae that produces limestone, a main ingredient of cement.

Supporter Spotlight

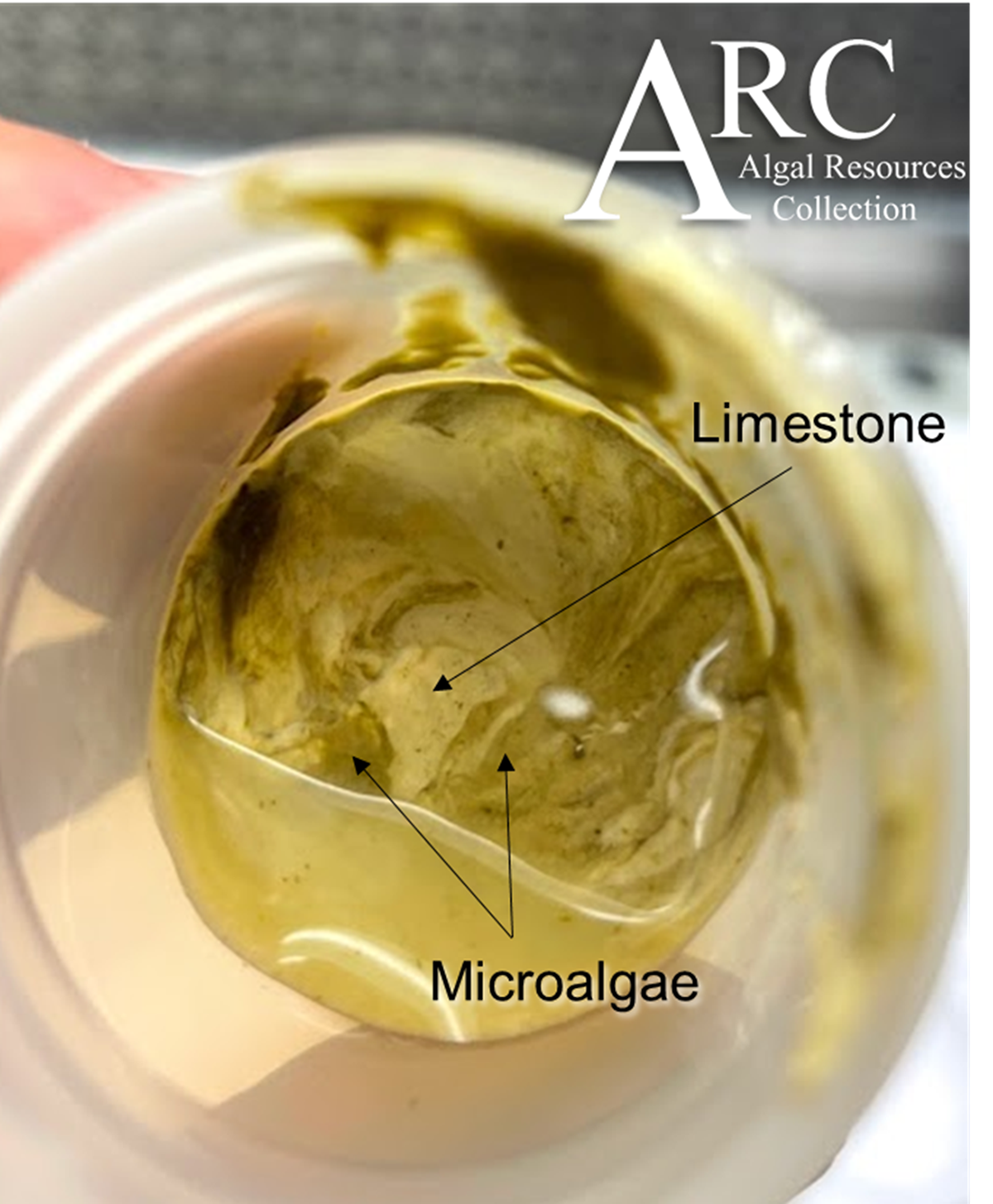

If produced in mass quantities, biogenic limestone, or that which is created by lab-grown microorganisms, could be used in the place of a percentage of limestone mined to make cement.

“So instead of having cement that is 100% made by limestone that you find in nature, we’ll have 50%,” Alves-de-Souza said.

That may not sound like a lot, she said, “but actually it can make a lot of difference. We need to show that’s possible.”

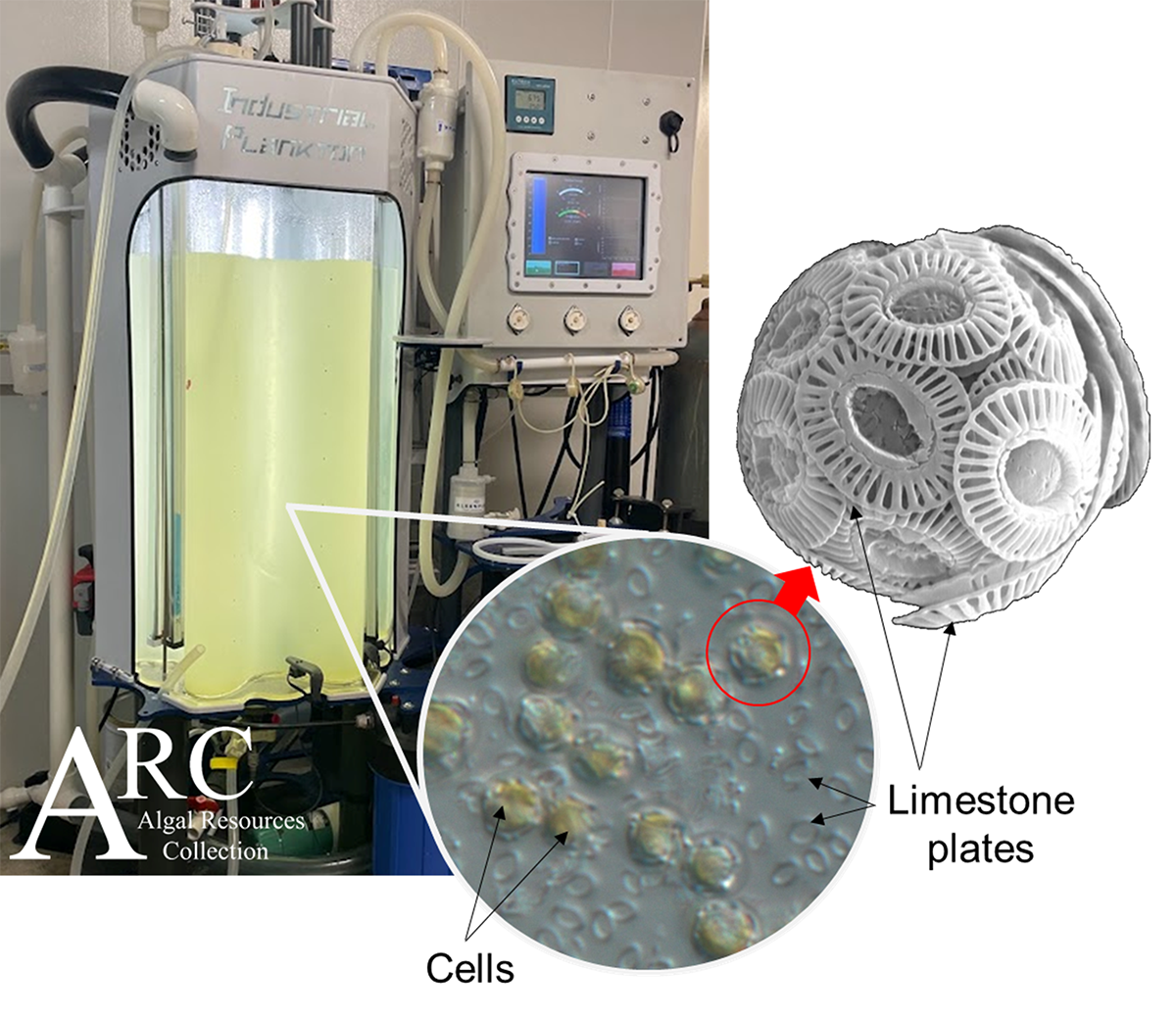

University of Colorado Boulder Associate Professor Wil Srubar, head of the university’s Living Material Laboratory, in 2020 began exploring how to grow limestone particles using coccolithophores, one-celled marine microalgae that produce calcium carbonate.

“It is a carbon negative form of calcium carbonate, or limestone, and that has real implications for the cement and concrete industry in the United States,” Srubar said.

Supporter Spotlight

Portland cement, the most common type of cement used throughout the world, is made from quarried limestone burned at high temperatures, which releases large amounts of carbon dioxide.

This process is responsible for 7% of annual greenhouse gas emissions.

Most atmospheric CO2 dissolved in seawater is rapidly converted to bicarbonate. Coccolithophores use this bicarbonate to create limestone, which is a form of carbon capture.

Srubar’s team discovered that substituting lab-grown limestone in the place of natural limestone creates a net carbon neutral way to make portland cement.

Replacing traditional methods of cement manufacturing would curtail about 2 gigatons of CO2 emissions each year around the world, “simply by using this limestone that we grow instead of quarrying it out of the ground,” he said.

To make the trade out work, coccolithophores will have to be produced in mass quantities.

Based on their calculations, Srubar’s team believes about 1 to 2 million acres of open pond systems would be needed to grow enough microalgae-producing limestone to meet the demand for cement production, which is about 90 million tons annually, in the United States.

About 100 million acres of land is used to grow corn in the United States.

“What we found is we need just 1% of that to satisfy the demand of cement production in the United States,” Srubar said.

This is where Alves-de-Souza comes in. Her lab is equipped to grow biogenic limestone in large volumes.

Using the knowledge Srubar’s team has on microalgae’s biology, ecology and physiology, Alves-de-Souza is testing the best conditions to grow mass quantities of coccolithophores.

“We are going to grow them and we are going to expose them to the conditions that we want and we’re going to select the cells that are growing better under these conditions. It’s a lot of experiments,” she said.

How microalgae get bicarbonates from salt water to form calcium carbonate is a process that depends on a variety of things, including the pH, or measure of acidity or alkalinity, and nutrients in the water.

Timing is also key because coccolithophores grow quickly and, if used in cement manufacturing, will have to be harvested at just the right time.

Alves-de-Souza began producing the microalgae in small amounts in her lab last August, making small adjustments to find the right balance of nutrients, the right amount of pH, and timing.

“I have figured out a lot and that’s why we’ve used preliminary data for the project,” she said.

That helped researchers obtain a $3.2 million grant split between UNCW, CU Boulder and the National Renewable Energy Laboratory from the U.S. Department of Energy Advanced Research Projects Agency-Energy.

The microalgae will be grown in the lab at UNCW in a 100-liter bioreactor and a 1,000-liter bioreactor. Alves-de-Souza will send monthly shipments of the microalgae produced in her lab to her collaborators at CU Boulder, who will extract not only limestone, but other biomass from the microalgae, including proteins, lipids and carbohydrates.

During the three-year project, Alves-de-Souza expects to produce at least 5,000 gallons of coccolithophore cultures.

“Right now, we are working with one culture, one microalgae, but the idea is that we are going to isolate to get more of these cultures from nature and at some time we are going to use artificial selection to get better cultures, cultures that are doing more of what we want. They are calcifying more,” she said. “We still have a lot to do.”

In order to bridge the gap to commercialization, Srubar’s team last year founded Minus Materials Inc., a startup to attract corporate partnerships.

Srubar, a co-founder and acting CEO, said Minus recently completed a pilot-scale project with a local concrete company in Boulder and has plans in place to produce ton-scale quantities of biogenic limestone within the next 12 to 24 months.

“I think this is a really exciting time for our team and we’re looking forward to not only embarking on this project, but also seeing this through to commercialization,” he said.